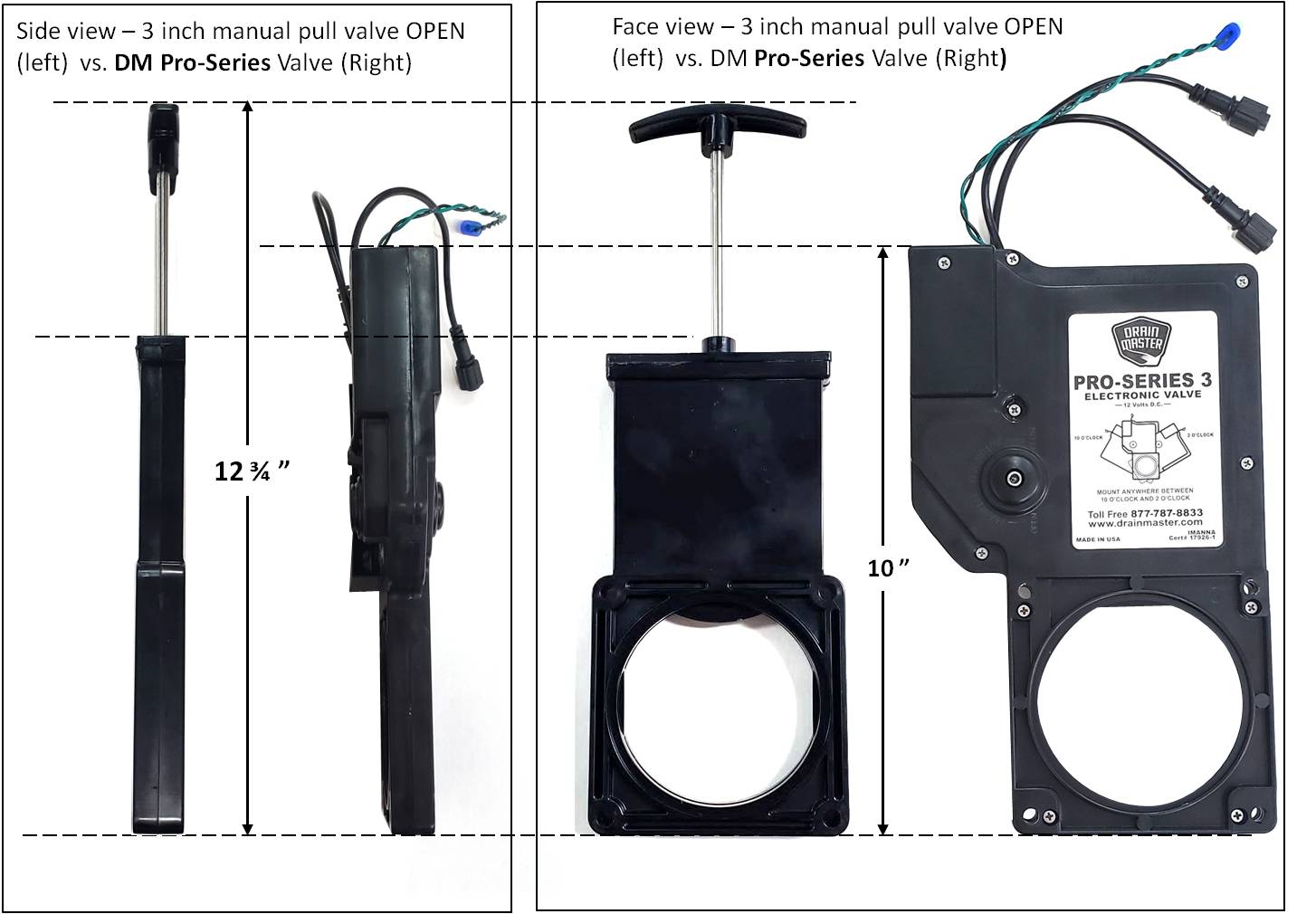

Pro-Series S3VT Kit [1 Valve 6027]

$484.84

Drain Master Pro-Series S3VT Valves come with a 5 year warranty !

6027 Single Valve kit includes:

• 1 Pro-Series S3VT valve with dual port module, waterproof IP66 rated

• 1 Single switch pre-installed in Snap-in Housing, sealed IP66, Carlingtech – with Super Bright Red and Green LEDs, highly visible in RV exterior locations

• 1 Single switch pre-installed in Snap-in Housing, sealed IP66, Carlingtech – with Super Bright Red and SOFT Green LED, unobtrusive in RV interior locations

• 2 Interface Cables, IP 66, 20 Ft (Custom lengths available)

• 1 Power connector pigtail with seals

• 1 Set of Seals, Lube and Hardware

Switch mounting style: Switch housings snap-mount directly to the panel

More information on pre-configured S3VT Valve kits, compatible products and optional accessories is available at: DM103 S3VT Valve Configuration Guide.pdf

Out of stock

Features

The Smart Sensing Valve Technology features:

On-board custom, slim profile Electronic controller

Waterproof IP66 rating

Small molded style connectors with easy-routing interconnect cables

Direct to Valve 12VDC Power- lossless regardless of switch to valve distance

Controller opens or closes valve in under a second

Push button triggered, no switch press time dependency

High accuracy solid state sensors and feedback control

Controller stops motor at precise target position

Stainless Steel gearing

Vastly improved reliability and precision

Lossless reverse polarity protection

Power-Up sensing – Valve homes to ‘Safe’ closed position at power up

Power-on Green LED indicator

Protection Seals on 12V power connector and included pigtail

Expandability – easy to add more Valves and switches

Adaptable to External controllers and Automation

RoHS and Lead Free compliant

Tech Data

KIT PN 6026-EXT TECHNICAL DATA

S3VT VALVE PN 6009

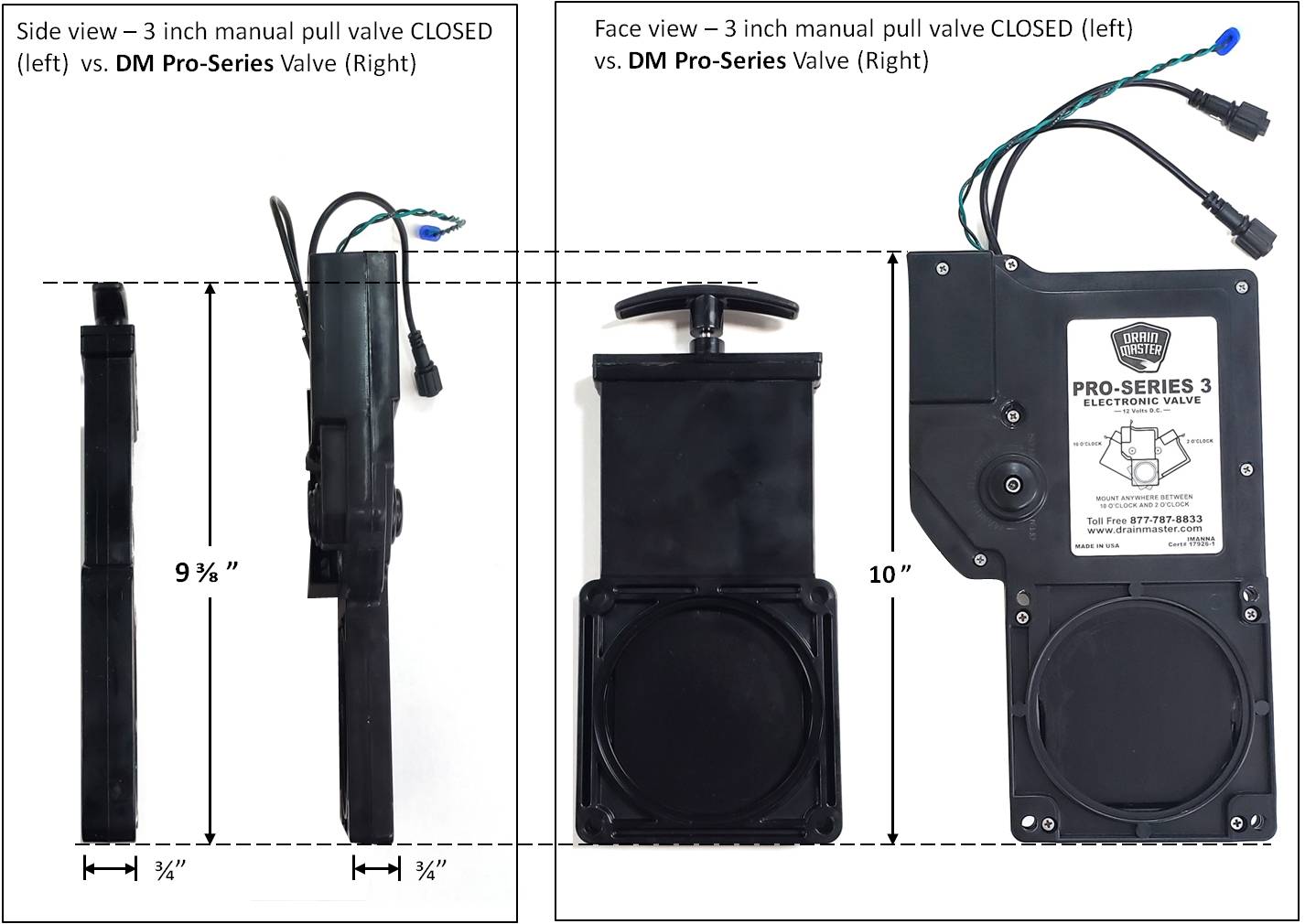

• 12 V DC, 3’’ Full flow valve

• On board Electronics Controller with feedback gate position control

• High accuracy Semiconductor position sensors

• IP 66 Compliant – waterproof, sealed electronics

• Reverse Polarity protected

• Power-On safe ‘homing’ to closed position

• Operating time: 0.5 sec Typical at 12 V; 0.75 sec max

• Sensors provide Red (Open), Green (Closed) LED status to operating switch

• 2 ports for 2 switches (2nd switch option)

• Port Interface: Waterproof IP66 connector when mated and secured to male

• Connector Type: Custom molded, 10 mm OD x 37 mm L, 4 pin female, gold plated contacts

• Screw-on protective cap (included on unused port if applicable)

• Compatible with 2 types of switches – for exposed or protected locations

• Green Power-On LED on the on board controller

• Back up Active motor safety: Internal timer 0.8-0.85 seconds

• Voltage range: 10.8 volts – 14.4 Volts. 12 V Nominal

• 12V power connector pigtail with seal included

• Stand by current under 50 ma with 2 switch LEDs active

• Slim profile, under ½”, on-board controller – fits tight spaces

• Internal gearing: 303 Stainless steel, Swiss made

• Durable ABS, injection molded Valve Body and Parts

• Manual Override from both sides of valve with 1/8” Allen key included

• Easily attached to 3″ ABS male or female bolt-on flange fittings. Mounting HW included

• Adaptable to most pipe sizes with proper fittings

• Special Seals Included

• Lubricant Dow Corning 111 included

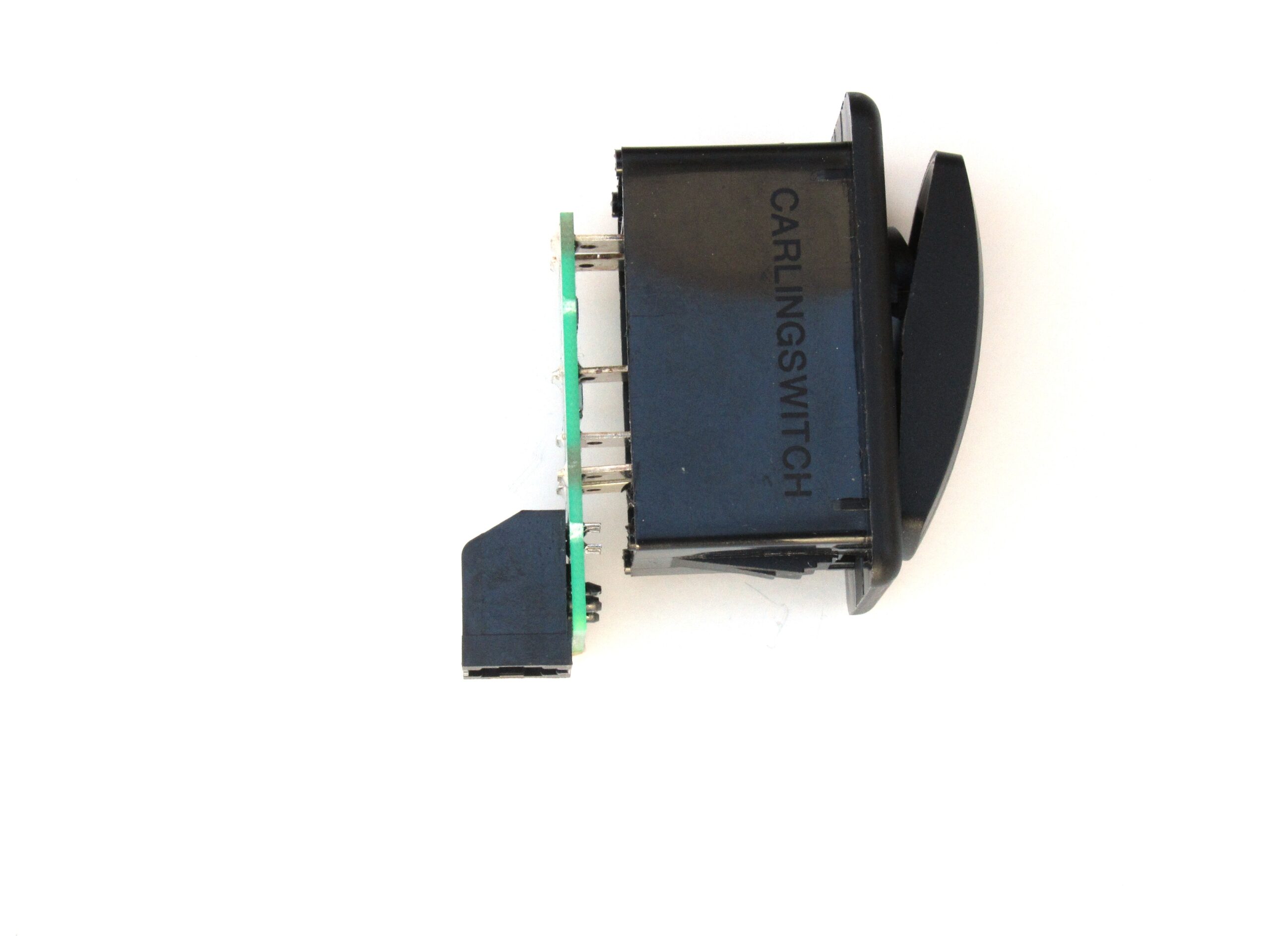

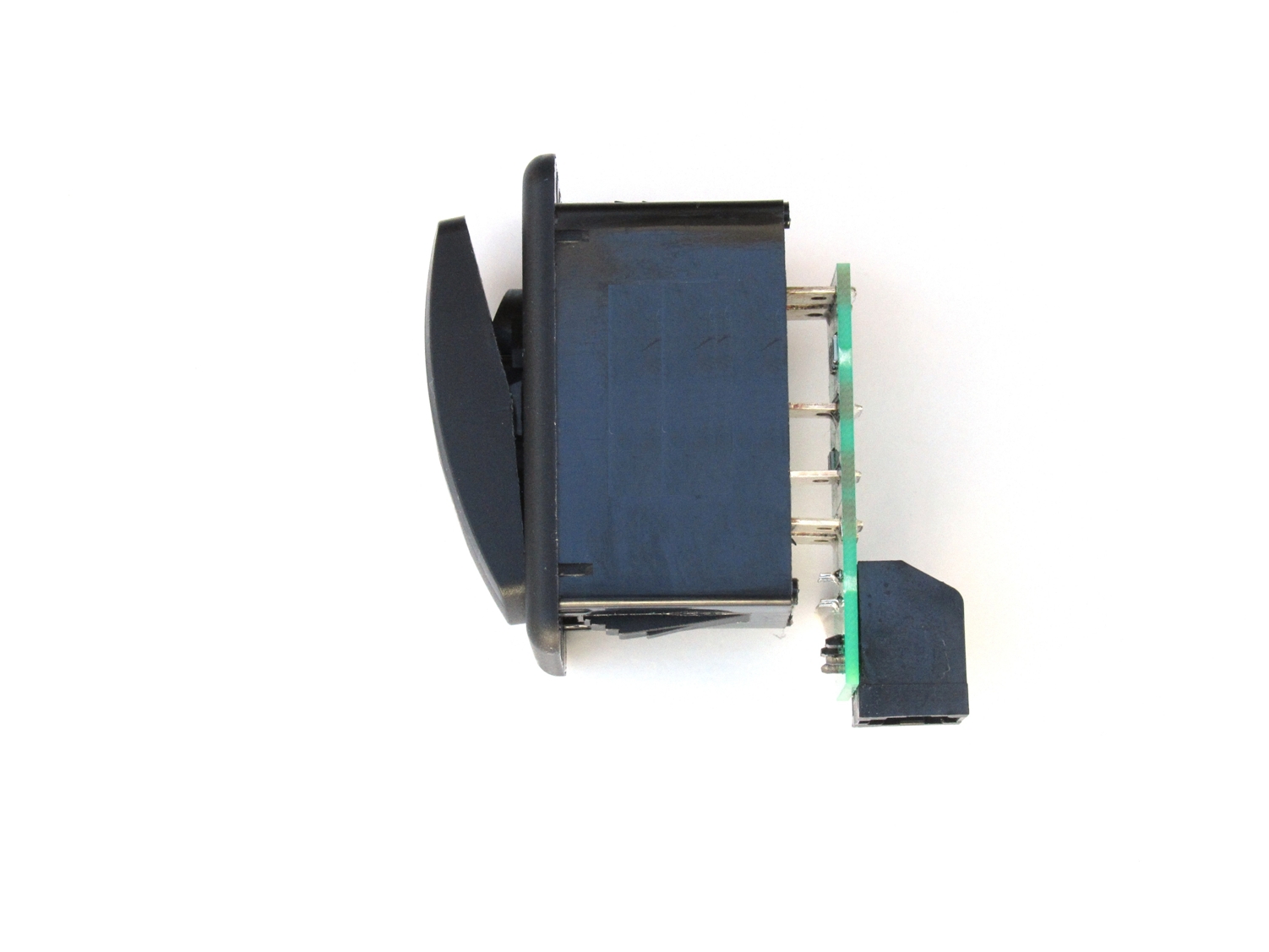

SINGLE SWITCH PN 5964-EXT

• Illumination: Internal Bright RED and Bright GREEN LEDs

SINGLE SWITCH PN 5964-INT

• Illumination: Internal Bright RED and SOFT Green LED

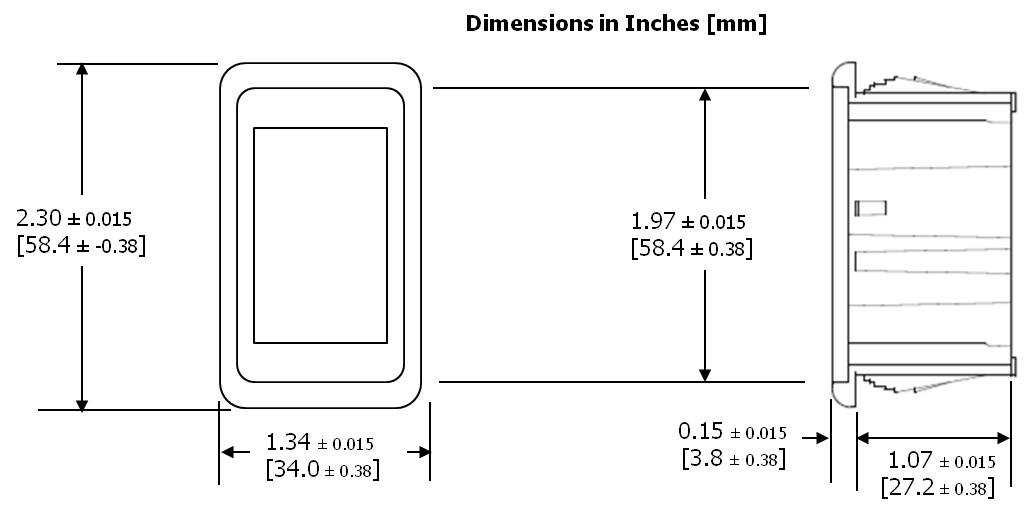

Tech Data common to both SINGLE SWITCH 5964-EXT and PN 5964-INT

• Mounting: Each Switch comes preinstalled in snap-fit housing

• Switch Type: Momentary contact rocker with custom PCB assembly

• Sealing: Switch to Housing sealed with closed cell gasket; Switch sealed with dual seals around LEDs and rocker stem

• IP rating: IP66 from front panel

• Hole cutout for snap fit housing: 0.99 inch x 1.90 inch (25.1 mm x 48.3 mm)

• Panel thickness : Min: 0.062 inch (1.57 mm) Max: 0.375 inch (9.52 mm)

• Rear clearance requirement: 1.92 Inch measured from front of panel (Housing seating surface)

• Interface: 6/4 RJ 11 socket, gold plated contacts, mounted on rear PCB assembly

• Actuator: Aesthetic symmetrically curved, black nylon

• Actuating force: 460 grams +/- 30, (4.5 N +/- 0.3)

• Actuating distance to rocker center: 20 mm

• Lens – Dual prismatic, clear polycarbonate set in rocker

• Operating life: 50,000 cycles min

• Industry certification: Switch meets MIL Std. 202F, MIL Std. 810C, UL 1500, ISO 8846, IEC 60529 and BS 5490

IP66-2 CABLE DM PN 5955-IP66-20’ Rnd. Cable Ass

• Type: AWM Style 2464 Cable

• Core: 4

• Wire: 4 x insulated cores, stranded copper, 7/30 per core, 26 AWG, Black Outer Sheath

• Cable OD: 3.5 mm (0.140 inch)

• Length: 20 Ft std.; (Custom lengths available)

• Temp Rating: 60 Deg. C

• Voltage rating: 150V

• Controller interface: Waterproof IP66 connector when mated and secured to female

• Connector Type: Custom molded, 12.9 mm OD x 36.5 mm L., 4 pin male, gold plated contacts

• Switch interface: 6/4 RJ11 Plug, Gold plated contacts, for stranded copper round wire

Installation

Pro-Series S3VT Valve Kit Installation

Kit installation involves 3 steps – a) Installing Valve b) Operator switch and cable c) 12 VDC wiring

Use the links below to S3VT Companion Documents

(Note: For Switches in Housings, Mono through Penta, use panel cutout and clearances in DM 114 instead of DM102)

Follow the instructions to complete the installation process

DM101 S3VT Valve Installation

DM102 S3VT Operating Switch and Cable Installation

DM114 Multi-Switch Housing Panel Cutouts and Clearances

DM104 S3VT 12V DC Wiring Diagram

PDF Files open in a new window – view in browser or save for off-line viewing or printing

Application

Application information on Pro-Series S3VT valve kits can be determined from:

DM103 S3VT Valve Configuration guide

PDF Files open in a new window – view in browser or save for off-line viewing or printing

Warranty

S3VT Pro- Series Drain Master Electric Valve MANUFACTURER’S FIVE (5) YEAR LIMITED PRORATED WARRANTY

Drain Master RV & Marine Inc. (henceforth referred to as Drain Master Inc.) warrants its S3VT Pro-Series Drain Master valves to be free of defects in materials and workmanship under normal use and service for a period of five years (60 months) from the date of delivery. Units determined by Drain Master Inc. to be defective under this warranty shall be replaced for no cost or at a reduced replacement cost calculated as follows:

0-24 mos. or less the valve is replaced free of charge.

Greater than 24 mos. to less than 36 mos., the valve is replaced at 80% off of the current retail price.

Greater than 36 mos. to less than or equal to 48 mos., valve is replaced at 40% off of the current retail price.

Greater than 48 mos. to less than or equal to 60 mos., the valve is replaced at 20% off of the current retail price.

If the valve was purchased as part of a kit, the current replacement valve price will be used in the equation. The replacement price does not include the cost of shipping, taxes, international duties, import fees, or any other related costs. These costs are the responsibility of the customer. However, the warranty will cover the cost of Ground shipping for replacement valves within the contiguous United States. Extra fees for expedited shipping are the responsibility of the customer. This warranty is transferable to a subsequent purchaser but only for the remainder of the unused portion of the warranty. The subsequent purchaser must provide a receipt to prove the original date of purchase.

This warranty covers S3VT Pro-Series Drain Master electric valves only. Accessories such as switches or extension cables carry a 1 year replacement only warranty. Fuses and fuse holders are excluded from this warranty and not covered.

To submit a warranty claim, an RMA number must be obtained by contacting the company. The product must be shipped (at the customer’s expense) within 15 days of obtaining the RMA number. Upon receipt, company will perform a series of tests on the valve to determine whether the valve is defective, or has been improperly installed, subject to improper voltage and damage due to negligent or abusive use, or normal wear and tear, including, but not limited to, those items on Schedule A.

REPLACEMENT VALVE WILL NOT BE SHIPPED UNTIL THE ORIGINAL PRODUCT IS RETURNED TO DRAIN MASTER INC. AND THE TESTING IS COMPLETED. Every effort will be made to complete testing within 30 days of receiving the returned valve. REPLACEMENT PER THE PRORATED SCHEDULE ABOVE IS THE ONLY REMEDY AVAILABLE UNDER THIS WARRANTY. Each replacement valve carries its own brand new warranty.

Specifically excluded from this warranty are (1) labor and (2) use of improper voltage and (3) damage due to negligent or abusive use or normal wear and tear, including, but not limited to, those items on Schedule A (following). Negligent, abusive, and other improper use of the valve voids this warranty.

IN NO EVENT SHALL DRAIN MASTER RV & MARINE INC. BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR LOSS OF PRODUCT OR TIME, OR FOR ANY DELAY IN PERFORMANCE UNDER THIS WARRANTY. Drain Master Inc. MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY. THIS WARRANTY SUPERCEDES AND/OR REPLACES ANY PRIOR WARRANTIES, IF ANY, ON SAME PRODUCTS. The validity, construction and enforcement of, and the remedies under, this limited warranty shall be governed by the laws of the State of California.

- Please send the product to: Drain Master, ● 400 Park Center Dr. Ste. 6 ● Hollister, CA 95023

- If requested email photos to: [email protected]

Any questions regarding this warranty should be addressed to: [email protected]

SCHEDULE A

Following are descriptions of typical situations where this warranty does not apply. Exclusion is not limited to these situations.

EXAMPLES OF NEGLIGENT OR ABUSIVE USE: Broken, kinked or melted cables, evidence of physical damage to the module, overstressing the manual override, stripping the gear due to aggressive stress, incorrect mounting- not following install zones.

Damage from exposure to excessive heat. Exposure to chemicals such as solvents, petrochemicals, paints, acids, alkaline materials, or other substances which cause damage. Over torqueing the mounting hardware. Use of seals other than those provided. Use of incorrect lubricant. Any physical damage to switch or any kind of mechanical damage or alteration to the switch. Use of the valve with other types of operating devices, such as touch panels, pdm’s, etc. without the approval of Drain Master Inc.

![Pro-Series S3VT Kit [1 Valve 6027]](https://drainmaster.com/rv/wp-content/uploads/sites/2/2023/09/6027-MSH1OS-E1OS-IR2-1.jpg)

![Pro-Series S3VT Kit [1 Valve 6027] - Image 6](https://drainmaster.com/rv/wp-content/uploads/sites/2/2024/06/T-Hawkins-PS-Intall-Good-Position-plus-Strapping-scaled.jpg)

![Pro-Series S3VT Kit [1 Valve 6027] - Image 10](https://drainmaster.com/rv/wp-content/uploads/sites/2/2022/02/4-Bottom-5964-scaled.jpg)

![Pro-Series S3VT Kit [1 Valve 6027] - Image 14](https://drainmaster.com/rv/wp-content/uploads/sites/2/2023/01/5964-Panel-cutout-002.jpg)

![Pro-Series S3VT Kit [2 Valves 6004]](https://drainmaster.com/rv/wp-content/uploads/sites/2/2024/02/6004-2-Plus-2-DSP-300x225.jpg)