HepvO 1.25 Inch Waterless P-Trap

$35.20

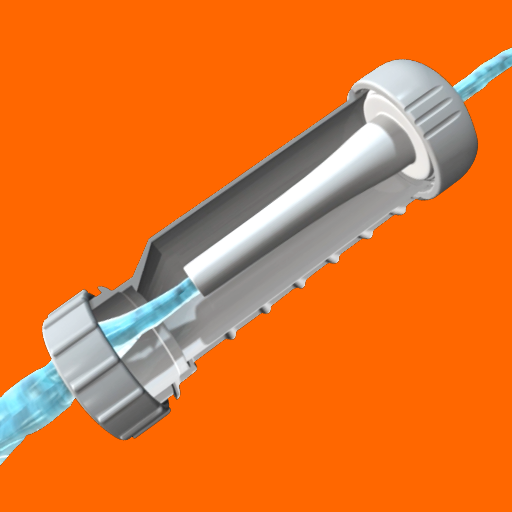

1.25 Inch Waterless P Trap Introducing the World’s Most Amazing Waterless Drain Waste Valve

Reviews

“The Hepvo valve is just what we needed for the tricky plumbing in our remodeled bathroom. It has been working great for the past year. Very happy with it.”

C. Meagher

“Awesome product! I’ve told several people about it. I installed one in my kitchen sink and one in my bathroom sink, both of which are in my rv certified tiny house.”

D. Bigelow

“I’ve had a HepvO valve installed in my Airstream for several years and it is great! No risk of freezing and I didn’t have to sacrifice any headroom in the shower. I couldn’t be happier.”

Jeff

Partnered with HepvO

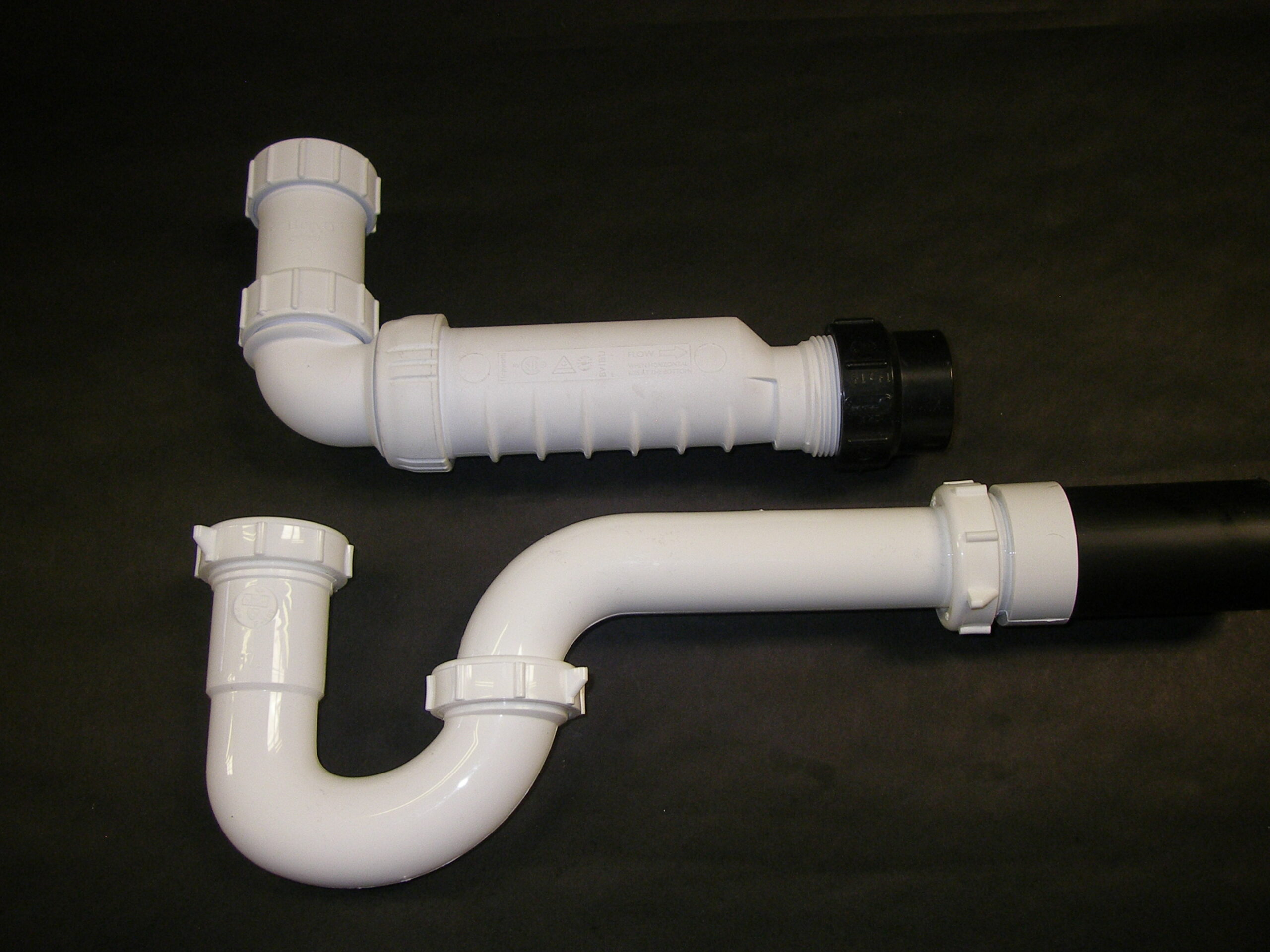

What is it? / Applications

HepvO® is the innovative hygienic Self Sealing Waste Valve. It replaces the traditional water-seal trap and prevents the escape of foul sewer air from waste discharge systems. Unlike conventional waste traps, HepvO® does not rely on trapped water to create a seal. Water seals are prone to failure by evaporation, siphonage and other mechanisms. Instead, HepVo uses a self sealing membrane which performs the same function as a water seal trap but without the risk of depletion or freezing.

HepvO® actively eliminates negative pressure within the waste system by opening and allowing in fresh air until a state of equilibrium with atmosphere is reached. This means that secondary venting of the waste system via the inclusion of air admittance valves in the waste system is no longer necessary.

Enhance Plumbing Design

The HepvO® valve means enhanced plumbing design and system efficiency, without compromising performance or risking the escape of foul air into the living space from the drain or sewer.

The HepvO® valve can be installed vertically or horizontally (with an adaptor) and is available in 1.5 inch and 1.25 inch. This enables valuable space-saving opportunities to be achieved.

Applications

|

|

How it Works

How it works:

HepvO® is a self sealing valve designed to close the waste connection below a sanitary fixture to prevent the escape of foul sewer air into the dwelling.

HepvO® unlike conventional waste traps, does not rely on trapped water to create a seal. Water seals are prone to failure by Evaporation, Siphonage and other mechanisms. Instead, uses a self sealing membrane which performs the same function as a water seal trap but without the risk of depletion or freezing.

The HepvO® Sanitary Waste Valve means enhanced plumbing design and system efficiency, without compromising performance or risking the escape of foul air into the living space from the drain or sewer.

Features:

- Waterless – no need for trap primer

- Admits Air – auxiliary venting not required

- One Way Valve – prevents foul odors

- No Siphonage. No Noise. No Smell

- Not vulnerable to evaporation or freezing

- Enables multiple fixtures to be located on the same waste branch

- Saves cost by eliminating air admittance valves and reducing the amount of pipe used

- higher flow rates and more rapid discharge from fixtures

- Can be used safely on all applications, even where discharge is intermittent and a regular tap would dry out

- Perfect to solve problems in existing failing systems and on applications where fixtures are only used occasionally, such as guest bathrooms, holiday homes, boats and mobile homes

Installation Detail

Click here to view the HepvO® Installation Instructions |

Click here to view the HepvO® product tech design guide |

Installation Steps:

- Cut the tube to length, allowing for the full compression socket depth, (preferably using an appropriate tube cutter).

- If using plastic tube remove any loose material from the end. If using metallic tube remove any ‘burr’, and file if necessary to remove any external sharp edges. Mark the socket depth on the tube, and check that the tube section to be joined is free of any surface damage which may affect the joint seal.

- Unscrew the cap from the outlet/inlet adaptor and slide the cap and rubber seal onto the tube.

- Insert the tube end fully into the socket.

- Slide the rubber seal and screwed cap up against the face of the socket, and tighten the cap by hand, (check that the cap is square to the body and does not ‘cross-thread’), hand tight should be adequate to form a proper seal.

- Threaded connections can be made to the inlet or outlet of the valve. At the outlet it is first necessary to remove the cap and rubber seal. If making connections to threaded components that do not have an integral seal (for example connection to DWV adaptors) PTFE/TEFLON tape should be applied to the thread prior to assembly.

Certifications

Certifications

Click here to view the IAPMO Certificate to US National Standard ASME/ANSI A112.18.8 |

Click here to view the CSA Certificate for use on RV’s |

Click here to view the SAI Certificate of Conformity to Australian Standard ATS5200 |

Click here to view the Condensate Drain Tech Solution |

FAQ's

Videos